High-Precision Resistance Welding Solutions for Automated Manufacturing

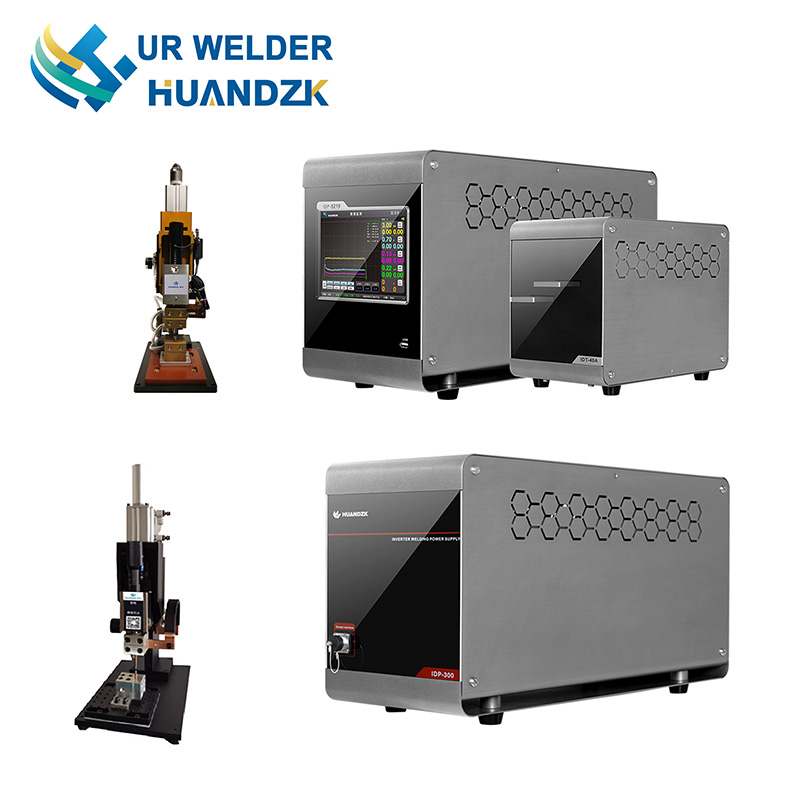

Modern manufacturing demands consistency, controllability, and repeatable weld quality. Advanced resistance welding gun systems combined with micro resistance welding technology are becoming the core equipment for high-precision metal joining in automated production lines. From motor components to electronic assemblies, resistance welding gun performance directly defines production efficiency and weld stability.

600" data-end="1017">In applications requiring ultra-fine energy control, micro resistance welding delivers exceptional results. Micro resistance welding enables precise current output, accurate pulse control, and minimal thermal impact, making it ideal for fine wire bonding, terminals, battery tabs, and miniature metal parts. With micro resistance welding, manufacturers achieve high yield rates while maintaining structural integrity.

For applications that demand strict geometric consistency, centerline resistance welding plays a critical role. Centerline resistance welding ensures balanced force distribution and uniform current flow along the weld axis. By integrating centerline resistance welding into automated fixtures, manufacturers reduce electrode wear and significantly improve welding repeatability. Centerline resistance welding is especially valuable in multi-point welding and robotic welding cells.

High-end production environments often benchmark performance against established brands such as sciaky resistance welder systems. A sciaky resistance welder is widely recognized for handling heavy-duty resistance welding gun configurations and large workpieces. By adopting similar control logic and power stability standards, modern resistance welding solutions can meet or exceed sciaky resistance welder performance expectations while offering higher flexibility.

In precision electronics and medical manufacturing, amada miyachi resistance welding is frequently referenced as an industry standard. Amada miyachi resistance welding emphasizes precise current regulation, fast feedback, and data traceability. Integrating micro resistance welding capabilities inspired by amada miyachi resistance welding allows manufacturers to meet stringent quality audits and automated inspection requirements.

Today’s smart factories increasingly combine resistance welding gun systems with micro resistance welding, centerline resistance welding alignment, and intelligent monitoring. Whether benchmarking against sciaky resistance welder solutions or aligning performance with amada miyachi resistance welding standards, advanced resistance welding platforms deliver stable output, scalable automation, and long-term production reliability.

By optimizing resistance welding gun design, enhancing micro resistance welding control, and implementing centerline resistance welding strategies, manufacturers gain a competitive edge in high-precision resistance welding markets worldwide.