In the precision processing field of modern manufacturing, resistance welding technology has become a core solution for metal connection due to its high efficiency, firmness and environmental protection. From auto parts to electronic components, from hardware products to new energy equipment, copper bar resistance welding machine, resistance welding press semi-automatic, inverter resistance welding machine and other equipment, combined with professional control for resistance seam welding system and welding control sensor by resistance, build a full-process precision welding system, injecting strong power into high-quality production in various industries.

As a core equipment for welding conductive materials, copper bar resistance welding machine is specially designed for materials with excellent conductivity such as copper bars and copper strips, overcoming the industry pain points of fast heat conduction and high welding difficulty of copper materials. Based on the principle of resistance heating, it quickly generates concentrated heat on the contact surface of copper bars by accurately applying pressure and current, realizing millisecond-level local melting and fusion. The conductivity and mechanical strength of the welding joint are comparable to the base metal. In fields such as new energy vehicle battery packs, high and low voltage distribution cabinets, and photovoltaic inverters, this equipment can complete reliable connection of copper bars of different specifications, effectively reducing contact resistance and energy consumption, and ensuring the safety of power transmission. Equipped with welding control sensor by resistance, it can real-time detect the resistance change during the welding process, adjust welding parameters dynamically, and avoid welding defects such as false welding and over-welding.

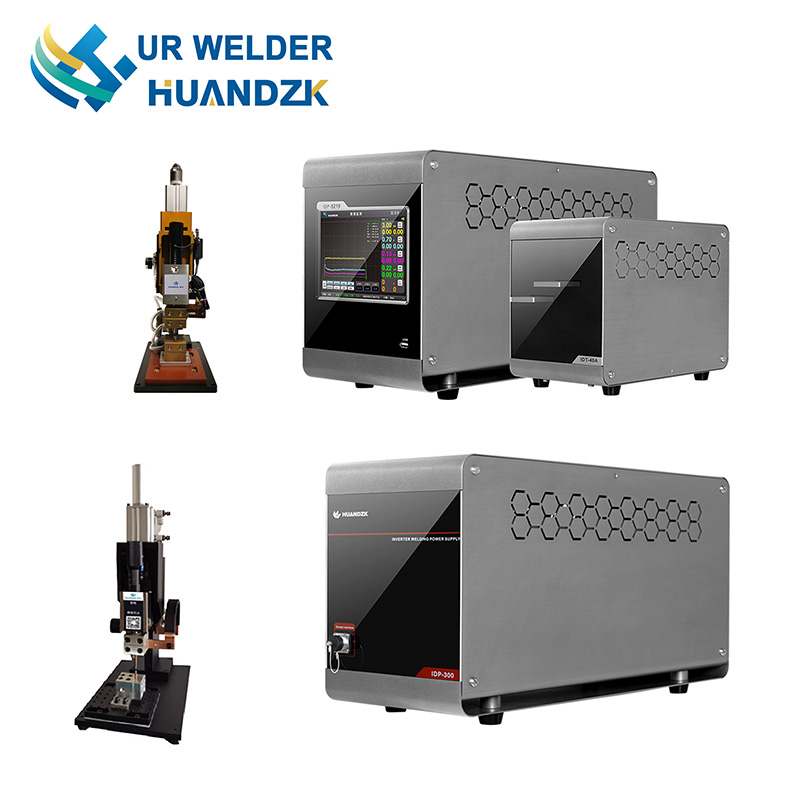

For small and medium-sized enterprises and production lines with semi-automatic operation needs, resistance welding press semi-automatic has become a cost-effective choice. It integrates manual feeding and automatic welding functions, which not only reduces the labor intensity of operators, but also ensures the consistency of welding quality. The equipment is equipped with a high-precision pressure adjustment system, which can flexibly set pressure parameters according to different workpieces, and cooperate with inverter resistance welding machine to achieve more stable current output. Compared with traditional welding equipment, inverter resistance welding machine has the advantages of small size, high energy efficiency and precise parameter control, which can significantly reduce energy consumption while improving welding accuracy.

Control for resistance seam welding plays a key role in continuous welding scenarios such as metal barrels and sheet metal. It can realize continuous and uniform welding along the weld seam, and adjust the welding speed, current and pressure in real time according to the seam shape and material characteristics. The matching welding control sensor by resistance can accurately identify the position of the weld seam and the change of contact resistance, feed back data to the control system in time, and realize intelligent adjustment of the welding process. This combination not only improves welding efficiency, but also ensures the airtightness and firmness of the weld seam, meeting the strict requirements of industries such as aerospace and food packaging.

With the continuous upgrading of manufacturing industry, the demand for precision and intelligence of welding equipment is increasing. Copper bar resistance welding machine, resistance welding press semi-automatic and inverter resistance welding machine, together with control for resistance seam welding and welding control sensor by resistance, form a synergistic technological system, which continuously breaks through the bottleneck of traditional welding technology. Whether it is mass production in large factories or small-batch customization in small workshops, this set of equipment system can provide personalized solutions, helping enterprises improve production efficiency, reduce costs and enhance core competitiveness in the fierce market competition.

In the future, with the integration of new technologies such as industrial Internet and artificial intelligence, resistance welding equipment will move towards a more intelligent and automated direction. The upgrading of inverter resistance welding machine will further improve energy efficiency and parameter precision, while the optimization of control for resistance seam welding and welding control sensor by resistance will realize full-process intelligent monitoring and control. Copper bar resistance welding machine and resistance welding press semi-automatic will also be upgraded according to industry needs, adapting to more complex welding scenarios and material types, and continuing to empower the high-quality development of modern manufacturing.