In the field of industrial metal fabrication, reliability, stability, and repeatability are the foundations of successful welding performance. Among the many power components available today, the AC welding power transformer continues to hold an important presence due to its robust structure, predictable output waveform, and excellent cost-performance advantages. Whether for automotive sheet metal, hardware parts, or appliance components, an AC welding power transformer provides consistent heat generation that ensures firm weld nuggets and stable long-term operation.

One of the most widely used products is the alternating current spot welder transformer. This transformer is optimized for welding steel sheets, coated materials, and mild steel components. Unlike high-frequency systems that require more complex circuits, the alternating current spot welder transformer uses a simple, durable iron-core structure to deliver strong current output. Factories appreciate its ability to work continuously under long shifts while maintaining low maintenance requirements.

The single-phase AC welding transformer is another essential component in traditional welding equipment. Its design allows predictable current flow with a sinusoidal waveform, making it suitable for general-purpose metal joining tasks. Many entry-level and mid-range resistance welders worldwide rely on the single-phase AC welding transformer because it offers stable output without the need for complicated control algorithms. This makes it ideal for workshops, equipment integrators, and mass-production environments where simplicity and durability are priorities.

For more demanding metal joining tasks, the AC projection welding transformer plays a critical role. Projection welding requires high peak current delivered in a short time window, along with controlled heat input to maintain the height and strength of the projection. The AC projection welding transformer provides the necessary current density to weld nuts, bolts, studs, and embossed parts. Whether used in automotive seat frames, compressor housings, or appliance brackets, this transformer ensures that every projection weld achieves consistent penetration and structural reliability.

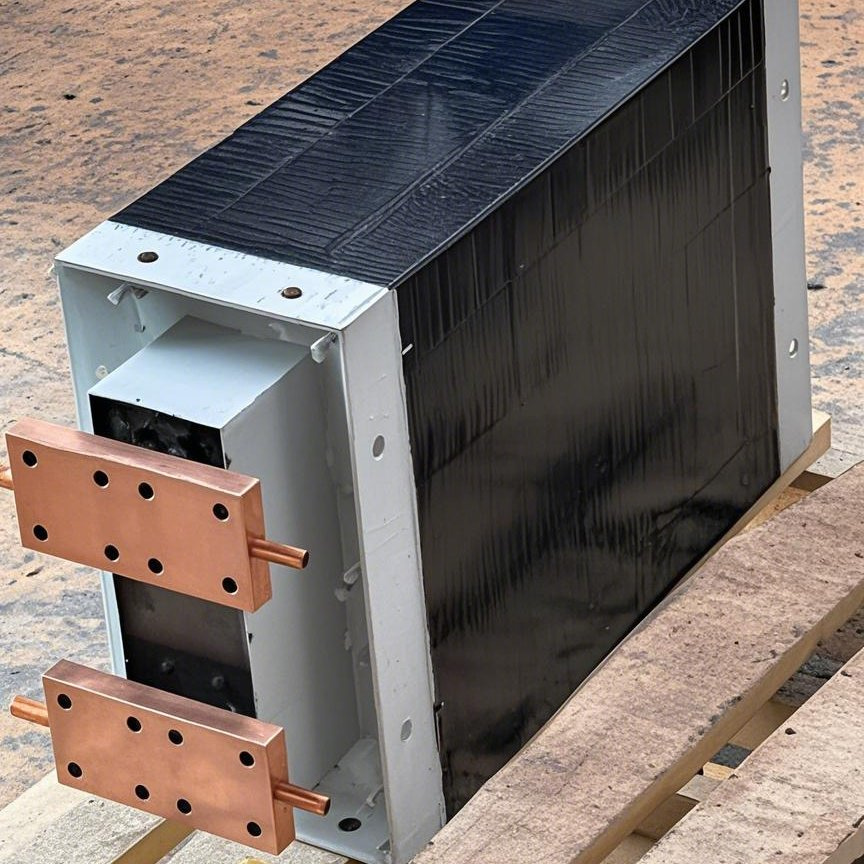

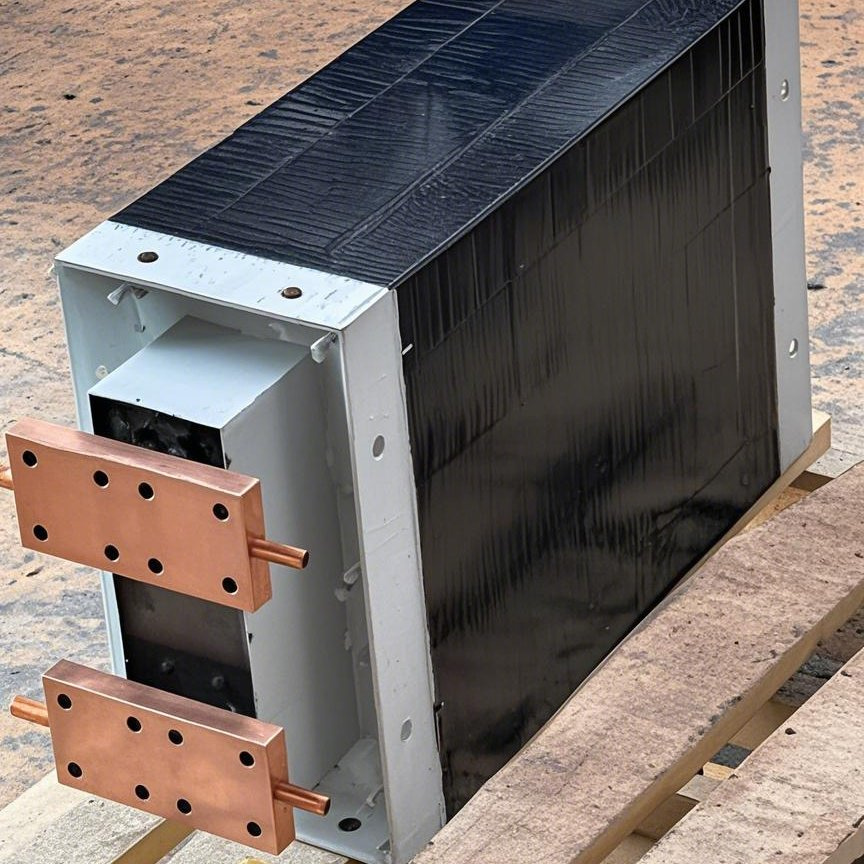

Another highly valued component is the heavy-duty AC welder transformer, designed for continuous high-load conditions. In many factories, equipment runs for many hours each day, and stable transformer performance is essential to maintaining product quality. The heavy-duty AC welder transformer withstands elevated temperatures, repeated current surges, and tough production cycles. Its reinforced coils, improved insulation, and optimized cooling channels give it a significantly longer lifespan than standard models. As a result, equipment downtime is minimized, and productivity is increased.

Across all these models—the AC welding power transformer, alternating current spot welder transformer, single-phase AC welding transformer, AC projection welding transformer, and heavy-duty AC welder transformer—manufacturers gain several important benefits. First is consistency. AC transformers deliver predictable current output, reducing weld variability. Second is durability. Their simple construction ensures long service life and minimal failure rates. Third is cost-efficiency. Compared to medium-frequency and inverter-type systems, AC transformer-based welders often offer a lower total cost of ownership.

Even as industries shift toward lightweight metals and advanced alloys, AC transformers still fill a critical role in many production lines worldwide. For carbon steel, coated steel, and standard structural materials, the balance of performance and affordability makes AC transformers a preferred choice. Their compatibility with classic mechanical welders ensures that many established factories can continue operating with low training requirements and high equipment familiarity.

As manufacturing evolves, companies continue to modernize equipment, but the AC transformer remains central in countless resistance welding machines. The components introduced in this article represent reliable and time-tested solutions that help factories achieve strong weld joints, stable cycles, and dependable long-term performance.