In today’s industrial welding landscape, the choice of transformer can make or break the efficiency and quality of your welding operations. A reliable welding transformer ensures stable power delivery, precise control, and consistent weld quality, whether for manual or automated systems. With the latest advancements in welding transformer technology, businesses can significantly boost productivity while maintaining superior results.

Inverter Welding Transformers have revolutionized modern welding setups. Compact, lightweight, and highly energy-efficient, inverter welding transformers utilize advanced electronic circuits to provide precise control over output current. This ensures a stable arc, reduced spatter, and consistent weld penetration. Industries ranging from automotive manufacturing to electronics rely on inverter welding transformers to achieve high-quality results while minimizing energy consumption.

For applications requiring fast and accurate power modulation, High Frequency Welding Transformers are an ideal solution. These transformers operate at higher switching frequencies, allowing for reduced size and improved energy efficiency without compromising performance. High frequency welding transformers are particularly effective in applications such as battery pack assembly, precision metal fabrication, and thin material welding. Their ability to deliver stable arcs at varying loads makes them a preferred choice for high-precision industrial tasks.

Resistance Welding Transformers remain a cornerstone of heavy-duty welding operations. They provide robust, reliable power for processes such as spot welding, seam welding, and projection welding. By converting electrical energy into heat at the contact point of metals, resistance welding transformers ensure strong, uniform joints with minimal defects. Industries that demand repeatable weld quality, such as automotive and construction, heavily rely on resistance welding transformers to maintain production standards.

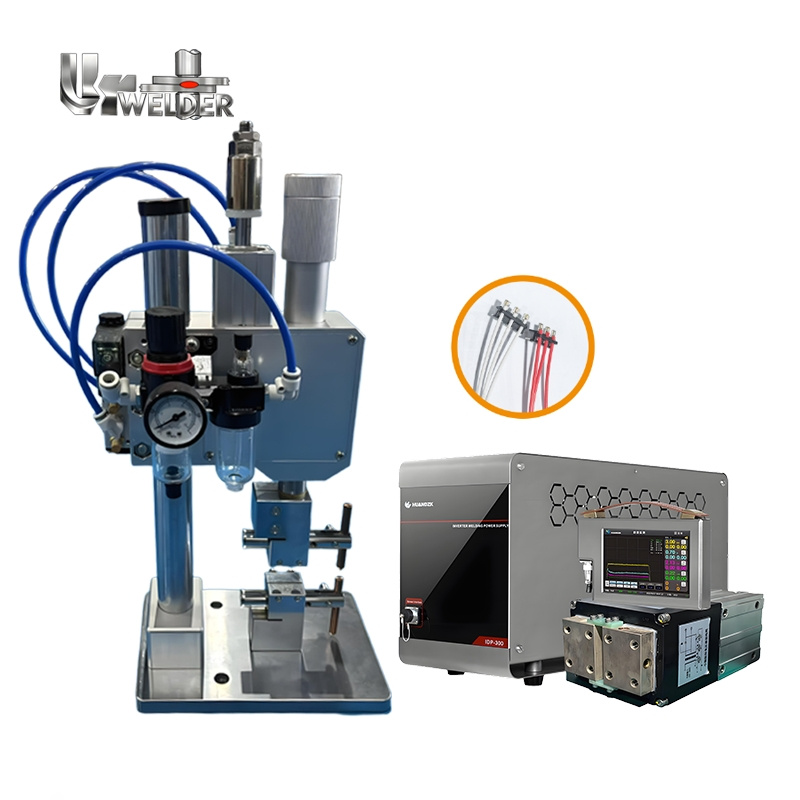

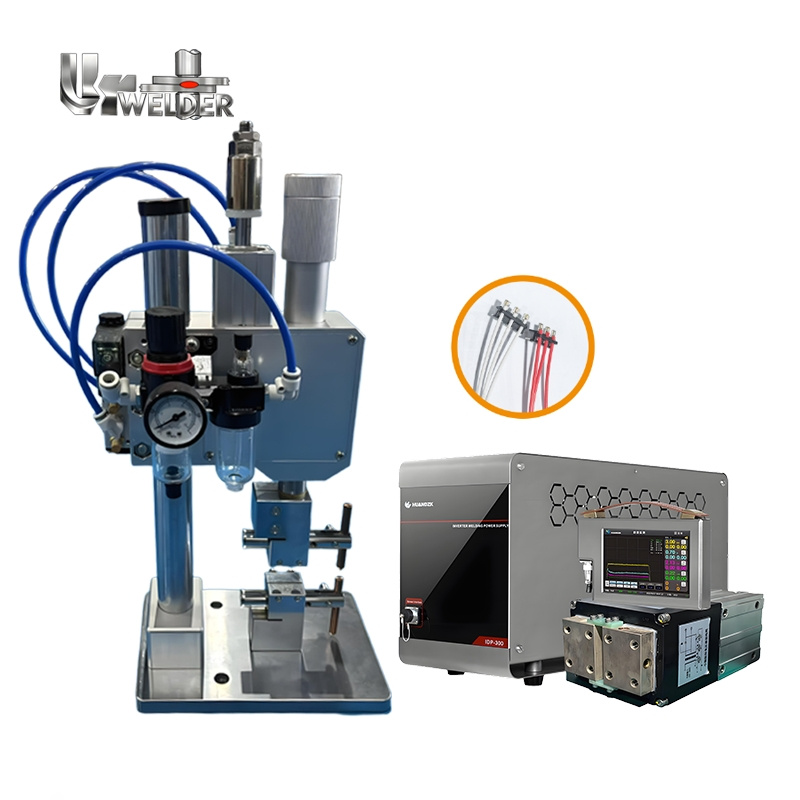

Spot Welding Transformers are a specialized subset designed to provide concentrated power for precise welding of small areas. Their design enables high current flow in short bursts, producing clean welds on sheet metal, battery tabs, and electronic components. Spot welding transformers are widely used in automotive body assembly, metal fabrication shops, and electronics manufacturing, where precision and speed are critical.

A versatile Welding Machine Transformer serves as the backbone for diverse welding applications. Designed to be compatible with multiple welding processes, these transformers offer flexibility without sacrificing performance. They can support various welding methods, including AC, DC, inverter, and resistance welding, making them ideal for facilities that handle multiple projects simultaneously. Investing in high-quality welding machine transformers ensures operational reliability, reduces downtime, and enhances overall productivity.

When selecting a welding transformer, consider key factors such as input voltage, output current, duty cycle, and cooling methods. Properly matched transformers maximize weld quality, minimize spatter, and improve energy efficiency. Additionally, modern transformers are equipped with safety features such as thermal overload protection and efficient cooling systems, ensuring long-term durability under continuous industrial use.

In conclusion, integrating advanced transformers into your welding operations is essential for achieving superior weld quality, consistent results, and operational efficiency. Whether you choose inverter welding transformers, high frequency welding transformers, resistance welding transformers, spot welding transformers, or versatile welding machine transformers, investing in cutting-edge technology will elevate your production capabilities. Explore our comprehensive range of welding transformers today and experience the perfect balance of precision, reliability, and efficiency in every weld.