High-Precision Welding Solutions for Modern Manufacturing

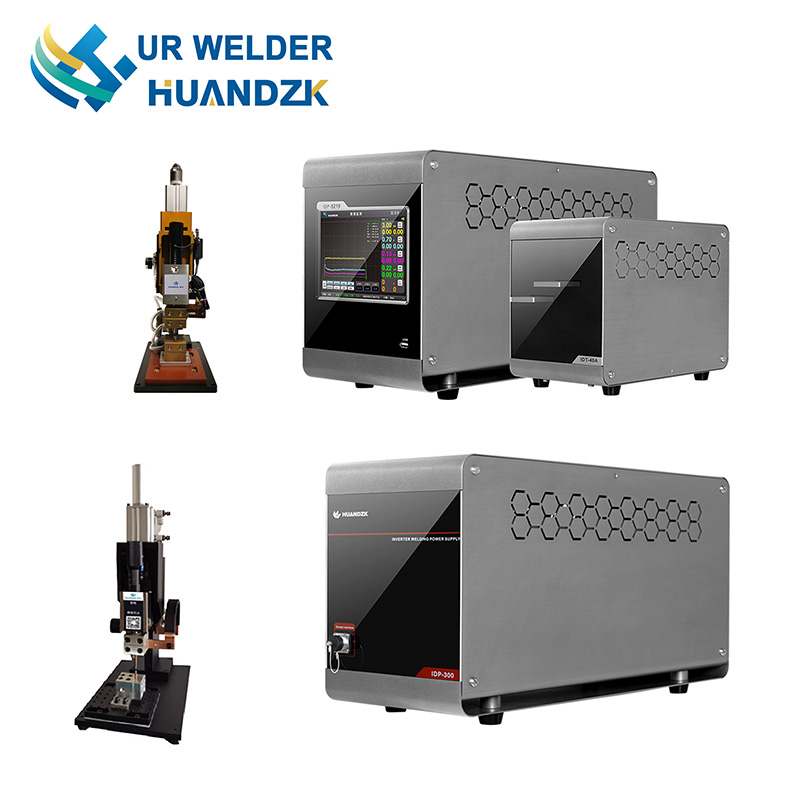

In today’s competitive manufacturing environment, a single head welding machine is essential for achieving stable output, repeatable quality, and high-efficiency production. Manufacturers across metal processing, tooling, and industrial assembly rely on a single head welding machine to maintain precise control over welding parameters while ensuring consistent results in continuous operation.

A silver welding machine is widely applied where high conductivity, clean joints, and minimal thermal impact are required. With a robust silver welding machine, production lines benefit from uniform weld strength, excellent surface finish, and reduced rework rates. The combination of a single head welding machine and a silver welding machine significantly improves overall production stability in precision-driven applications.

For flat material processing and structural joining, a sheet welding machine delivers reliable performance under demanding cycle conditions. A high-quality sheet welding machine supports stable pressure control, accurate current output, and long-term durability. When integrated into automated lines, the sheet welding machine enhances throughput while maintaining consistent weld integrity across different material thicknesses.

Safety, repeatability, and process control are key drivers for choosing a sequre welder. A well-designed sequre welder ensures stable operation, minimizes production risks, and supports continuous industrial use. By combining a sequre welder with a single head welding machine, manufacturers achieve higher confidence in quality control and long-term operational reliability.

In tooling and cutting applications, a saw blade welding machine plays a critical role in delivering strong, uniform joints for demanding mechanical performance. A precision-engineered saw blade welding machine supports accurate alignment, consistent weld strength, and excellent fatigue resistance. Paired with a silver welding machine, the saw blade welding machine helps manufacturers meet strict quality standards while improving production efficiency.

Across diverse industries, integrating a single head welding machine, silver welding machine, sheet welding machine, sequre welder, and saw blade welding machine into a unified production strategy creates measurable advantages. These systems support stable current output, precise timing control, and reliable long-term operation under industrial workloads.

By adopting advanced welding solutions built around a single head welding machine, manufacturers enhance productivity, reduce defect rates, and strengthen their competitive position. Whether focusing on flat materials, conductive joints, safety-critical welding, or cutting tool production, the combined use of a silver welding machine, sheet welding machine, sequre welder, and saw blade welding machine delivers consistent performance and scalable manufacturing success.