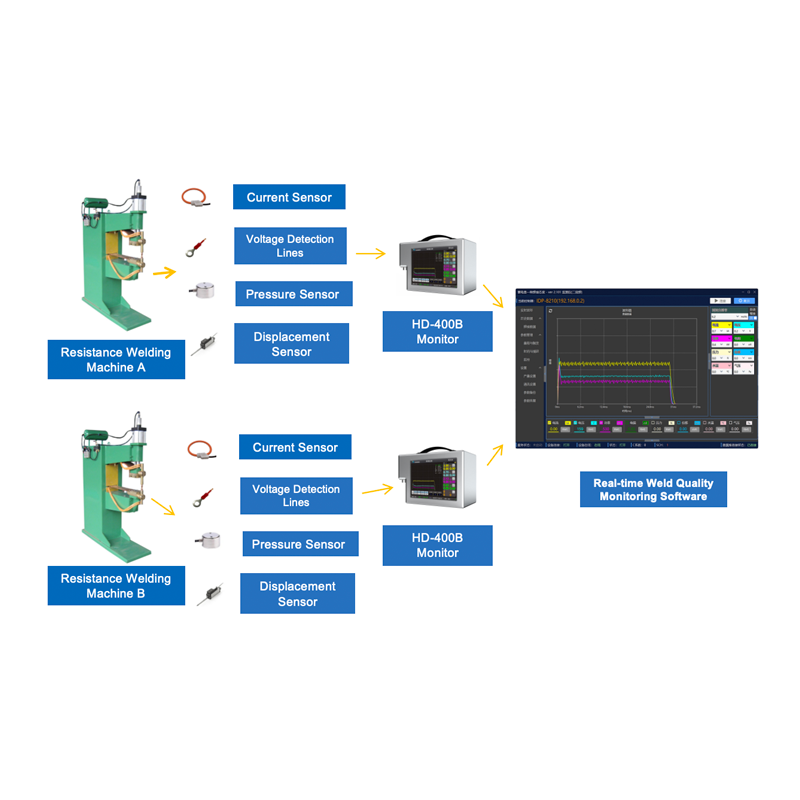

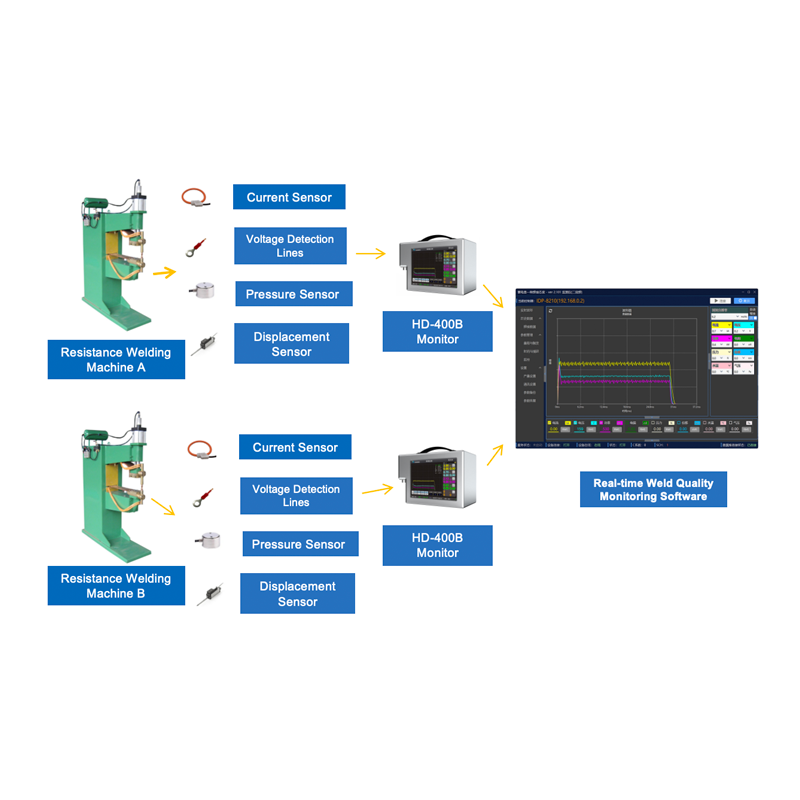

In modern precision manufacturing, stable welding quality determines the performance and reliability of every product. The Huandian HD-400B Welding Monitor is an advanced welding monitor designed to ensure high-accuracy, real-time control of the entire welding process. With cutting-edge hardware and intelligent software algorithms, it provides manufacturers with comprehensive welding quality control and data traceability capabilities.

The HD-400B resistance welding monitor is equipped with a high-speed 20 kHz sampling system that captures current, voltage, power, and displacement signals during each weld. It records the complete waveform, enabling detailed welding data analysis and precise evaluation of every welding pulse. Whether in automotive electronics, lithium battery tabs, precision connectors, or stainless-steel mesh welding, it ensures repeatable and consistent results.

Thanks to its high sensitivity and stability, the Huandian HD-400B Welding Monitor can quickly detect common welding defects such as poor contact, missing parts, pressure deviation, or abnormal discharge. The intelligent waveform comparison function automatically identifies deviations from standard parameters, helping operators take corrective action before quality issues occur. This makes it an ideal solution for high-volume production lines that demand zero-defect welding.

The monitor features an intuitive touch interface and supports both standalone and networked operation. Data can be transmitted via USB or Ethernet for centralized management, production traceability, and process optimization. The welding data analysis software offers waveform storage, trend comparison, and statistical reports—essential tools for process engineers who aim to improve product quality and production efficiency.

Compared with traditional welding inspection methods, the HD-400B welding monitor provides non-destructive, real-time inspection with millisecond-level precision. It not only enhances quality control but also reduces production downtime and material waste. Combined with Huandian’s advanced resistance welding monitor technology, it allows full process monitoring from initial setup to final output, ensuring reliability even under the most demanding industrial conditions.

Huandian has specialized in resistance welding power supplies and monitoring instruments for over a decade, serving hundreds of global manufacturers with solutions that match the quality of leading brands such as Miyachi and Bosch. The Huandian HD-400B Welding Monitor continues this legacy—delivering accuracy, intelligence, and confidence to every weld.

For manufacturers seeking to upgrade their production lines, the HD-400B Welding Monitor is not just a device—it’s a powerful partner for achieving consistent welding quality, data-driven decision-making, and long-term reliability in modern industrial manufacturing.