The Power of Machine Spot Welding in Modern Industry

In today’s fast-paced manufacturing world, machine spot welding plays a crucial role in ensuring high-speed, reliable, and uniform metal joining. Whether you are building automotive frames, electrical enclosures, or stainless-steel assemblies, the spot welder has proven to be one of the most efficient solutions. This process delivers strong joints without additional filler materials, making it both cost-effective and environmentally friendly.

A welding machine spot setup offers unparalleled repeatability and control. Its precise current and pressure management ensure that each weld is identical, maintaining quality consistency across production lines. As industries push for higher efficiency, manufacturers increasingly rely on spot welding devices that integrate monitoring systems and automated feedback loops for real-time quality control.

Why Spot Welding Devices Are Transforming Production Lines

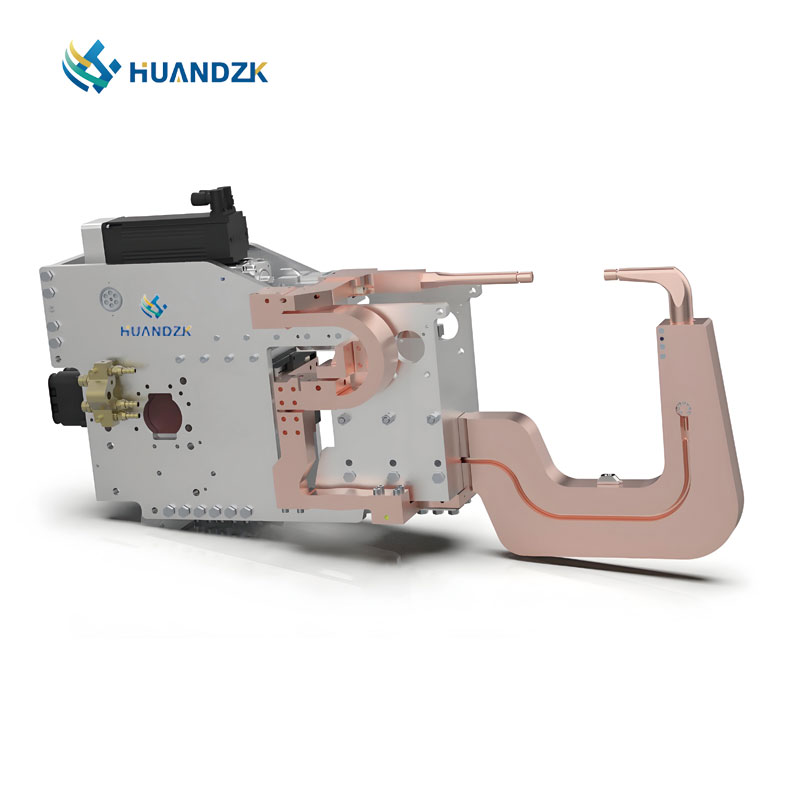

Modern spot welding devices are more than simple machines — they are intelligent systems that guarantee precision and reliability. They come equipped with programmable controllers, pressure sensors, and energy regulators to fine-tune the welding process. This level of control helps eliminate spatter, reduce electrode wear, and increase operational life.

In high-volume facilities, such as spot welding plants, automated spot welders work in tandem with robots and conveyors, achieving output levels that manual welding could never reach. The seamless coordination between robotic arms and machine spot welding units results in faster cycle times and minimal human intervention, drastically improving production efficiency and consistency.

The Versatility of the Tack Welder in Precision Assembly

A tack welder is a compact yet powerful tool used to make temporary joints or pre-weld positioning marks. In industries such as aerospace, automotive, and electronics, tack welding ensures parts stay aligned before final machine spot welding. This method prevents material distortion and enhances overall assembly accuracy.

Combining tack welding with full-scale spot welder systems allows manufacturers to streamline operations, minimize rework, and improve precision across all fabrication stages. Whether used for light sheet metal or high-strength steel, the tack welder provides unmatched control in the pre-weld stage.

Spot Welding Plants for Scalable and Automated Production

A well-designed spot welding plant represents the future of industrial automation. Equipped with intelligent welding machine spot systems, these facilities are capable of producing thousands of perfect welds per hour. Advanced process monitoring ensures each joint meets strict quality standards, even under demanding production schedules.

The latest spot welding plant designs include inverter-based power supplies that optimize current flow and reduce energy consumption. These upgrades improve weld quality while supporting sustainability goals by lowering operational costs and carbon emissions.

Choosing the Right Spot Welder for Your Business

Selecting the right spot welder depends on factors such as material thickness, production volume, and desired automation level. For heavy-duty applications, large-capacity machine spot welding systems with integrated feedback control are ideal. In contrast, compact spot welding devices are perfect for precision electronics, battery assembly, or stainless-steel mesh welding.

Investing in a high-quality spot welding plant or tack welder ensures long-term stability, improved throughput, and reduced downtime. The combination of automation, precise energy control, and intelligent process monitoring transforms ordinary production into a seamless, high-efficiency operation.

Conclusion

As industries evolve toward automation and sustainability, machine spot welding, spot welders, and spot welding devices are redefining how manufacturers approach metal joining. From flexible tack welders to fully automated spot welding plants, these technologies deliver the strength, speed, and precision required for modern production. Choosing the right welding machine spot system means investing in consistent quality, reliability, and future-ready manufacturing performance.